BMW will turn to Redwood Materials for recycling of batteries from its EVs, plug-in hybrids, and mild hybrids in the U.S., the automaker announced Thursday.

The agreement, which covers the BMW, Rolls-Royce, and Mini brands, as well as BMW's motorcycles, will see Redwood work directly with BMW dealerships, distribution centers, and other U.S. facilities to recover batteries at the end of their useful lives. BMW claims 95% to 98% of critical minerals like lithium, cobalt, nickel, and copper will be recycled.

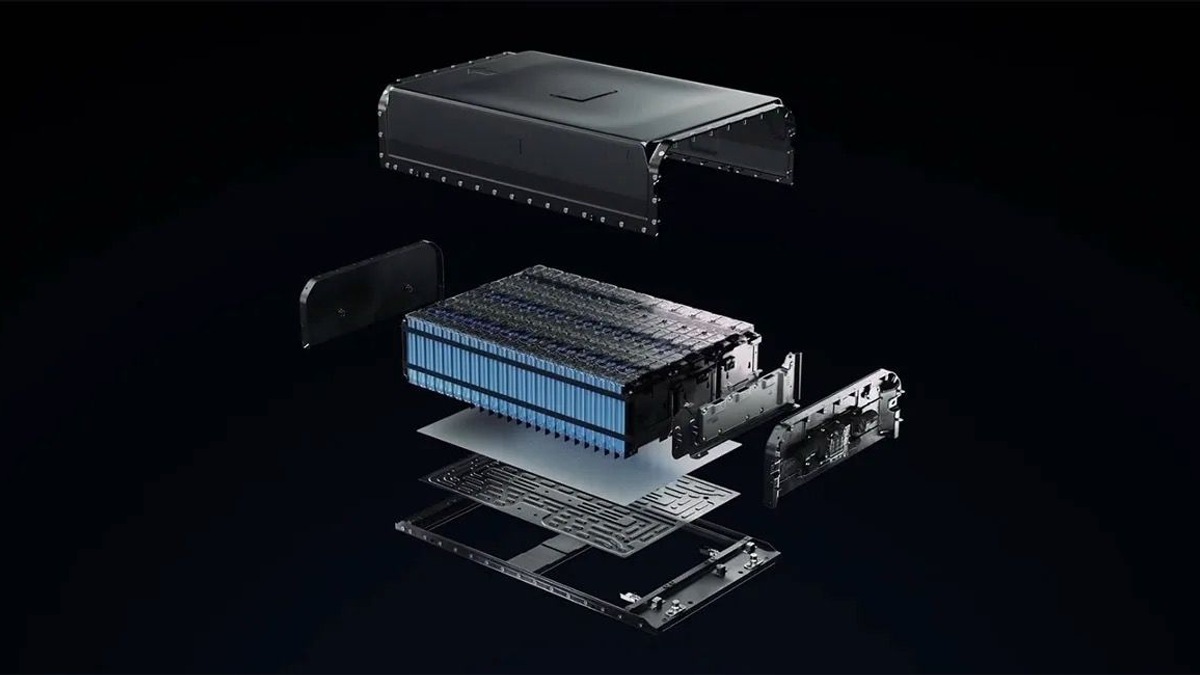

BMW partners with Redwood Materials on battery recycling

Redwood's recycling processes can reduce energy use by 80%, CO2 emissions by 70%, and water use by 80% compared to mining and refinement of new minerals, according to BMW.

Founded in 2017 by former Tesla CTO JB Straubel, Redwood is building a recycling facility in Charleston, South Carolina, that will be relatively close to BMW manufacturing facilities. The automaker has an assembly plant in Spartanburg and is building a battery plant in Woodruff. AESC, which supplies battery cells to BMW, has a plant in Florence.

Redwood Materials

BMW aims to build at least six fully electric models in the U.S. by 2030. In the nearer term, the automaker will ramp up production of its next-generation "Neue Klasse" EVs at plants outside the U.S. The first model, an SUV, will enter production in Hungary in 2025, followed by a sedan in 2026. The SUV will also be built in Mexico starting in 2027.

Redwood, which received a $2 billion loan from the U.S. Department of Energy in 2023, currently operates a recycling facility near Reno, Nevada. It also counts Ford, Toyota, and the Volkswagen Group's Audi and VW brands among its customers.