- VW's PowerCo could eventually make up to 80 gigawatt-hours of solid-state cells annually

- QuantumScape and PowerCo will combine forces to scale up production

- Production timeline and location weren't specified

Volkswagen’s PowerCo battery unit and the solid-state battery tech firm QuantumScape on Thursday announced a path toward the industrialization and mass-production of solid-state lithium-metal batteries for electric vehicles.

Through an agreement, in the form of a non-exclusive license, PowerCo will be able to make up to 40 gigawatt-hours of battery cells annually using tech from the solid-state firm, with the option to up that to 80 gigawatt-hours—enough for a million EVs annually.

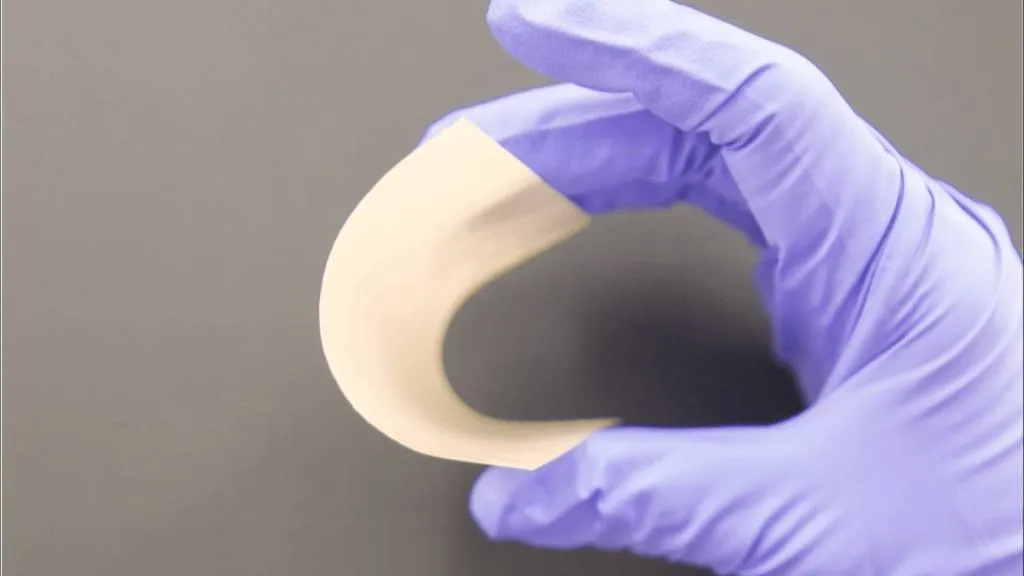

QuantumScape ceramic separator

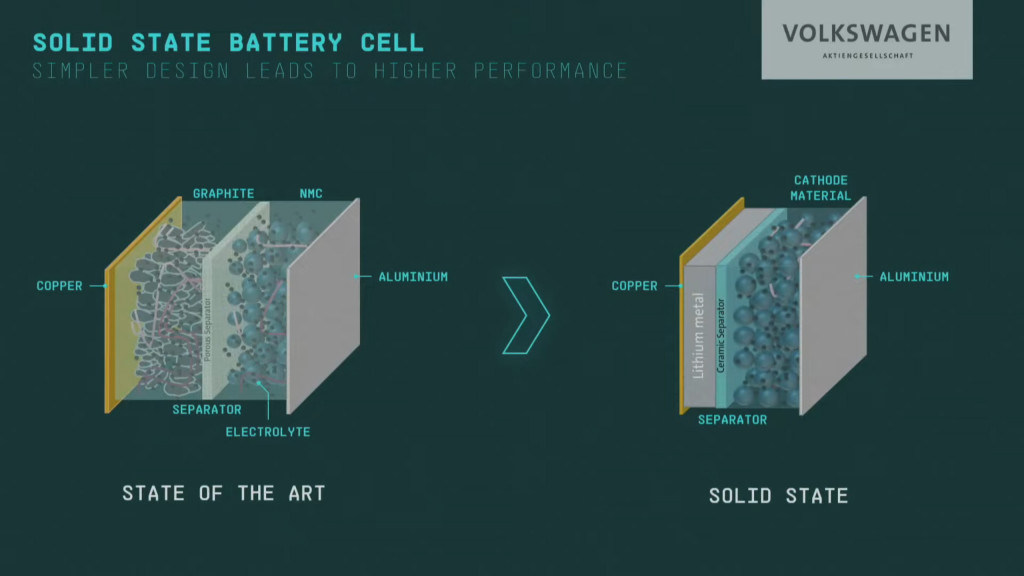

QuantumScape’s solid-state tech uses ceramic separators to allow a pure lithium-metal anode for higher energy and power density, with faster charging. As with other solid-state battery cell technology, QuantumScape has long ago proven that the idea is valid in a laboratory and smaller-scale environments, but scaling up mass production—for use over years in vehicles—has been the challenge.

To that, the companies say that they’ll combine core competencies, with “a combined workforce initiative” to accelerate the scaling-up of production and these cells’ integration into VW’s vehicles.

A location for the potential future manufacturing of solid-state cells was not disclosed, nor was a timeline.

VW Salzgitter cell facility

Volkswagen broke ground on its first EV cell “gigafactory” in July 2022, at the same time it formalized the PowerCo. business unit overseeing it. The facility in Salzgitter, Germany, serves as a hub for VW’s global battery activities and the starting point for what VW called a “global battery offensive” created around localized battery production by market and a vertically integrated battery supply chain aiming to cut cell costs by 50%.

That German battery factory is producing a new prismatic unified cell format that’s due to be used with the automaker’s upcoming Scalable Systems Platform (SSP) for electric vehicles starting in 2026 and will eventually be installed in 80% of the EVs from the VW Group by the end of the decade.

VW Power Day - solid-state composition

At its 2021 Power Day, VW called solid-state battery tech its “end game” in the shift to EVs, noting that it didn’t see the tech arriving until 2025 or later—in small volume at first. It saw solid-state tech as enabling 80% fast-charges in just 12 minutes.

VW has seen solid-state cells and QuantumScape as part of its long-term plan for more than a decade already. It’s been collaborating with the firm since 2012. Toyota is developing solid-state cells with Panasonic and sees the tech “ready for commercial use” by 2027 or 2028. Honda sees them as enabling affordable small EVs, while Nissan is working to develop its own solid-state cells and sees potentially game-changing EV packaging advantages from them.